Lean Production

The Best Ideas and Equipment from Japan, Europe & America

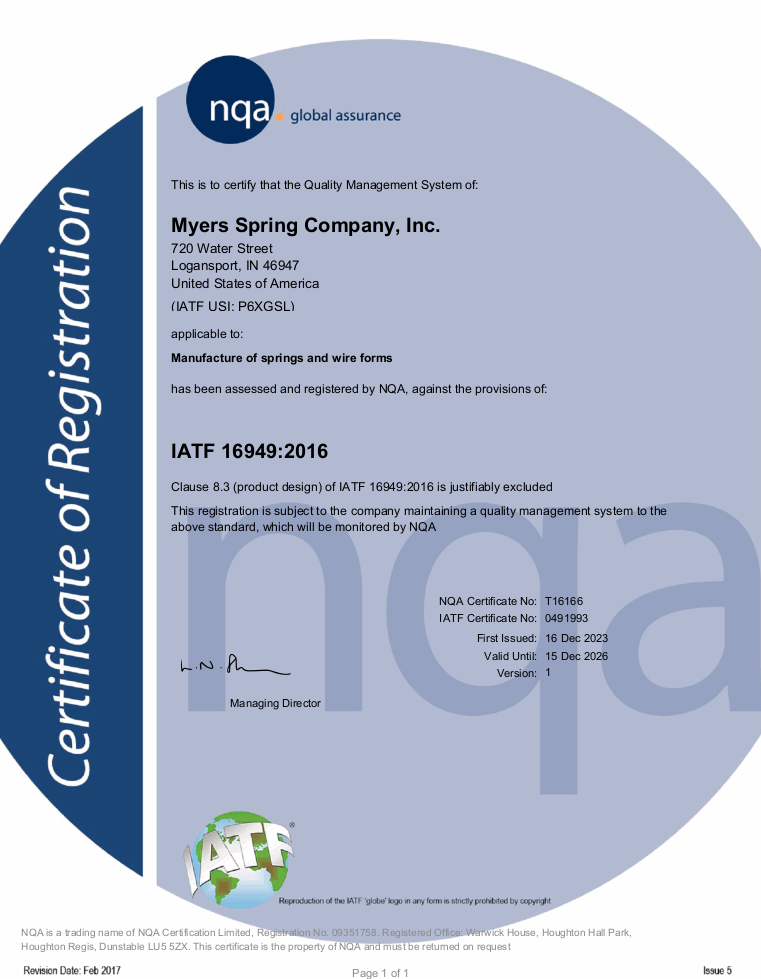

Under the leadership of Todd Miller, Myers Spring works to bring to the industry the world’s most advanced lean production techniques and technologies. This continual effort not only produces springs, wire forms, and other products of exceptional quality, it also creates exceptional savings.

Depending on the specification, Myers Spring may employ the following in producing your springs and parts:

Single Piece Flow Production and Packaging

Myers Spring prefers to produce and package in a single piece flow. Because no more than one out-of-spec pieces can be produced at a time, this method helps ensure product quality while reducing scrap. Packaging one item at a time also prevents the mixing of similar parts, and each box of product can bear a unique serial number.

Pull System Production and Inventory Management

Myers Spring can provide a just-in-time (JIT) production and inventory service for your springs and parts. The pull system allows for lower-cost production, and you avoid all inventory carrying costs.

Advanced Product Quality Plannning Checklist

Myers Spring employs a proprietary advanced product quality planning checklist to ensure top quality at every stage of the manufacturing process.

CNC-Controlled Dual-Point Coiling

In a break with the North American tradition of single-point coiling, Myers Spring introduced this technology in 1994. Widely used in Japan and Europe, dual-point coiling vastly decreases the incidence of tool marks on the inside diameter, typically the most stressed area of a spring. Myers Spring employs Bobbio and Simplex Rapid coilers from Italy.

CNC-Controlled Down Feed and Crush Grinding

Depending on the application, Myers Spring uses both down feed and crush grinding. Our down feed grinding process, the most advanced down feed method on the planet, reduces both the HAZ (heat-affected zone) and deformation burrs on the spring ends by monitoring the temperature of every spring we make DURING the grinding process if necessary. Myers Spring employs Wafios grinders from Germany and Moyer grinders from Indiana.

CNC-Controlled Wire Forming

CNC-Controlled Wire Forming

At Myers Spring, we utilize the highest quality and latest technology wire forming equipment from around the planet assures quick delivery times and the highest possibly quality.

Statistical Process Control (SPC) and Machine Capability Reports

Myers Spring employs cutting-edge methods of control to ensure top quality and proper specifications at every stage of the production process.

Computerized Visual Inspection

Multiple methods of automated visual inspection make sure your springs and parts are on specification. Even 100% sorting is available.

Purdue University - Manufacturing Extension Partnership (MEP)

All of our products are made from the highest-quality materials and can be packaged in tangle-free packaging. Click here to learn more.